What is a SKU & How To Create Effective SKUs

Whether you sell a dozen different products or several thousand, tracking and managing inventory is an essential part of managing a Shopify store.

Knowing exactly what you’ve got in stock (and where it’s located) at any given time isn’t simply a matter of logistics; it also has ramifications for marketing, sales, and customer support.

Which brings us to a key element of the inventory management process: the humble SKU.

In this in-depth guide, we’ll explain:

- What is a product SKU

- Why SKUs are important

- How to create and manage SKUs

What is a SKU Number?

A SKU (stock-keeping unit) — pronounced “skew” — is a unique product identifier used to track and manage inventory from supplier to customer.

Up to 12 characters long and comprising letters and numbers, SKUs are specific to each retailer. Different SKU numbers represent different products, based on factors like:

- Color

- Size

- Style

- Manufacturer

- Category

- Price

Can Two Products Have the Same SKU Number?

Ideally, no.. You want each product to have its own unique SKU to aid with inventory management.

However, SKUs are internal, so it’s up to you to make them unique. Many platforms such as Shopify do not enforce this.

It’s also totally possible for two separate products to have identical barcodes or UPC numbers.

Confused about the difference between stock-keeping units, barcodes, and UPCs? Let us explain…

SKU vs. UPC Codes

To the untrained eye, SKUs and Universal Product Codes (UPCs) look pretty much identical, but they have different properties and uses:

| SKU | UPC |

|---|---|

| Typically from 8 – 12 characters and numbers | Always 12 numbers |

| Used for internal inventory management | Used for external tracking and point-of-sale identification |

| Set by individual retailers | Standardized by the Uniform Code Council |

| Identifies product traits | Identifies manufacturer and product |

Because of these differences, it’s common practice for retailers to utilize both SKUs and UPCs for inventory and sales management, with SKUs used for internal operations and UPCs for external tracking.

It’s also worth noting that UPCs are required to sell products on Amazon, while Walmart requires suppliers use either a UPC or GTIN.

SKU vs. Barcode

A barcode is the series of black lines used by retailers when processing a customer’s order.

Barcodes are essentially a visual, scannable representation of the SKU or UPC (although they aren’t necessarily the same as either).

Here’s how barcodes differ from SKUs:

| SKU | Barcode |

|---|---|

| Alphanumeric code | Machine-readable visualization |

| Customized to meet the needs of the retailer | Standardized by bodies like the Uniform Code Council and the Global Standards Organization |

| Unique product identifiers used for internal inventory management | Used to identify products at point of sale or during the shipping process |

| Come in whatever format the retailer chooses | Come in different formats, including UPC and European article numbers (EANs) |

Like with SKUs and UPCs, it’s not uncommon for businesses to use barcodes and SKUs together, with SKUs handling the internal inventory management side, and barcodes supporting external identification and tracking.

Why Are SKUs Important and What Are Their Benefits?

On a basic level, SKUs help you keep track of stock levels.

But there’s more to stock-keeping units than that. Here are six ways they’re important:

Accurate Inventory Tracking

SKUs give retailers the power of accurate, real-time inventory tracking.

Given that each product has its own stock-keeping unit, businesses can easily determine stock levels on an individual item, helping them understand:

- When they need to order more stock

- How much stock to order

Streamlined Operations

Manual stock-keeping is a labor-intensive process. And it’s also highly susceptible to miscounts.

As such, many retailers automate their inventory management using SKUs — such as automatically reordering products when stock levels drop beneath a certain level.

This frees up time for employees to add value in other areas of the business (and also eradicates human error).

In fact, using other digital tools like inventory managers, order management software, or warehouse management systems allow you to automate many SKU-related tasks — such as generating reports, tracking inventory levels, and syncing stock across platforms. In addition to inventory-specific tools, it’s also worth considering solutions that support your team’s operational efficiency, especially if you manage a growing team across multiple locations or warehouses. For example, a workforce time clock app with GPS tracking helps you track staff working hours, manage shift schedules, and ensure adequate staffing during busy fulfillment periods. This kind of tool streamlines operations by accurately tracking employee work hours. This not only improves payroll accuracy but also helps managers monitor productivity and assign staff to inventory-related tasks more efficiently.

Improved Customer Service

Out-of-stock products don’t just affect sales and revenue; they can damage your reputation.

According to one study, three-quarters of consumers feel less loyal to a retailer after encountering product unavailability, while three-fifths feel less confident about continuing to buy from a store experiencing frequent stocks.

Accurate inventory tracking doesn’t mean you’ll never encounter stock issues.

But it does ensure that stock levels displayed on your website are accurate. So they’ll never purchase something, only to be told that the item isn’t actually available.

And the more accurate your inventory tracking, the easier it becomes to give customers a realistic timeline for when sold-out products will be back in stock.

Enhanced Data Analysis

Inventory tracking with SKUs opens the door for improved ecommerce analysis, allowing you to gather data on:

- Sales trends

- Inventory turnover rates

- Customer behavior

This can help you make smarter, data-backed decisions on everything from pricing to promotions.

Better Communication

Given that SKUs are unique to specific items, they give you a simple — and accurate — way to discuss individual products with your supply chain partners and other stakeholders.

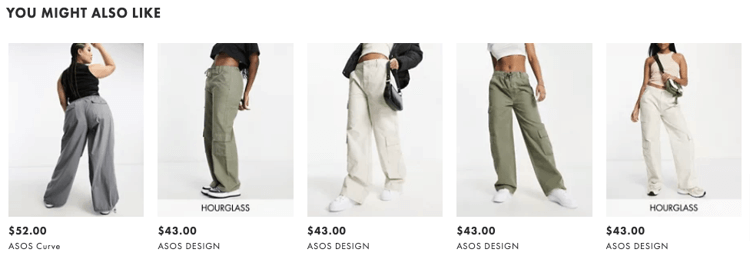

Improved Marketing Campaigns

Stock-keeping units also have a bunch of marketing-related applications, allowing you to recommend similar items at the bottom of product pages, on order confirmation pages, and in email and social campaigns.

They also make it easier to track product sales, which helps with tracking the performance of your marketing campaigns.

What’s more, because stock-keeping units are specific to the retailer, if a customer sees the SKU for a T-shirt, they wouldn't be able to do a Google search to comparison shop that same shirt on a different store.

Displaying the SKU in your e-commerce marketing materials also gives customers a simple way to reference the item. For instance, shoppers viewing this product…

…can easily say: "I'd like to order the FBDO107 T-shirt."

How Are SKUs Used?

We’ve already looked at a few common use cases for SKUs (and the benefits of using them).

Now, let’s dig further into how SKUs are used across different industries and systems.

Common Industries That Use SKUs

Brick-and-Mortar Retail

Physical retailers use SKUs to keep tabs on inventory levels and sales in brick-and-mortar stores, helping them identify top-selling products and understand when items need to be restocked.

E-commerce

Online retailers use stock-keeping units in the same way as traditional retailers, but applied to websites rather than physical stores. SKUs give e-commerce retailers the tools to alter pricing in line with customer demand and quickly order new stock across key collections.

Manufacturing

SKUs aren’t just found in the retail world. Manufacturers use them to track materials and components, ensuring they have sufficient inventory to complete current and future projects.

Wholesale

Wholesalers use SKUs to track inventory and sales for products in their warehouses, allowing them to identify popular items and adjust stock levels to meet demand from buyers.

Logistics and Distribution

Logistics businesses need to know where products are at all times. So they use SKUs to track movement throughout the supply chain, from point of origin to final destination, ensuring products arrive on time (and in the correct amounts).

Assigning and Managing SKUs

Different industries and businesses take different approaches to assigning and managing SKUs.

That’s all well and good — after all, stock-keeping units are totally customizable.

Despite this, some approaches are common across businesses and verticals, because they just make sense. Follow these steps for assigning and managing your SKUs:

- Determine Your SKU System

This might sound obvious, but you shouldn’t assign SKUs before determining your SKU system structure, including:

- The format of your SKUs (e.g. alphanumeric codes)

- Character length (between eight and 12 characters)

- The categories and subcategories you use to organize products

- Assign SKUs

Having defined the structure of your SKU system, you can start assigning SKUs to products.

Remember: each product should have a unique SKU to help you track inventory levels and sales data.

- Record and Track SKUs

Take a record of all your SKUs, updating it each time you add new products.

That way, you can easily identify when products are selling well or need to be restocked.

- Implement SKU Management Software

Unless you only have a tiny number of products, you’ll almost certainly want to invest in an inventory management or enterprise resource planning (ERP) solution.

These tools allow you to automate many SKU management-related tasks, such as generating reports and tracking inventory levels.

- Regularly Review and Update SKUs

Get into the habit of regularly reviewing your SKU system to ensure it’s still fit for purpose. This might involve:

- Adding new products

- Tweaking SKU categories

- Updating existing SKUs to reflect inventory changes

Examples of SKU Systems

Not sure how to structure your stock-keeping units? Let’s take a look at some common SKU systems:

Sequential

Arguably the most straightforward approach, sequential systems involve assigning a unique, sequential SKU number — such as 00000001, 00000002, 00000003, and so on — to each product. These numbers might be assigned at random or based on a specific factor, such as age or name.

While easy to begin with, this strategy can quickly become difficult to manage, especially if you have a lot of different products (and regularly introduce new ones).

Alphanumeric

A slightly more sophisticated approach is to adopt an alphanumeric system of letters and numbers, such as ABC12345.

This approach allows you to manage more products than a simple sequential system, but it can still become unwieldy, fast.

Hierarchical

With a hierarchical SKU system, you start by segmenting products into categories and subcategories, each represented by its own SKU element.

For instance, consider the SKU A001-01-02, whereby:

- The first four characters (A001) represent the product category

- The fifth and sixth characters (01) represent the subcategory

- The final two characters (02) represent the product in question

It should be obvious that this approach makes it far easier to organize large numbers of products than with a sequential or alphanumeric system.

Color and Size

Another potential strategy — one that’s especially useful for businesses with high quantities of product variants — is to assign SKUs based on product color and size.

For example, let’s consider the SKU BLUE-ME-SH, whereby:

- The first four characters (BLUE) represent the product’s color

- The fifth and sixth characters (ME) mean the product is of medium size

- The final two characters (SH) mean the product is a shirt

Why It’s Important To Come Up With a Good SKU Structure

If you really want, you can assign SKUs based on the dates of birth of your favorite celebrities or just pick a bunch of random numbers and letters.

However, there are clear advantages to creating meaningful, well-designed product codes:

- Provides at-a-glance visibility into product features

- Makes it easy to create new SKUs in a logical, ordered way

- Allows products to be grouped based solely on their SKU

How To Create Effective SKUs

So we’re agreed: creating logically-structured SKUs is a good thing. Here’s how to do it…

Use a Consistent Format

Without a consistent format — such as a set number of characters or a specific pattern of letters and numbers — it becomes far harder to manage and track SKUs.

Include Product Information

Your SKU should help you easily identify the product in question, incorporating details like manufacturer, color, size, product category, and various other characteristics.

Avoid Using Special Characters

Don’t use special characters (like symbols and punctuation marks) because they can mess with barcode scanners and don’t “play well” with some inventory management solutions.

Make Them Easy to Remember

We’re not suggesting you should be able to reel off every SKU in your Shopify store. But you (and your employees) should at least be able to remember how your SKUs work, thereby making it easy to figure out the correct stock-keeping unit for any given product.

Plan for Growth

Create a scalable SKU system that’s able to grow with your business. Be sure to leave space for new products, categories, and variants. And develop a process for replacing or retiring outdated SKUs as your inventory changes over time.

Consider Automation

Enterprise resource planning software and inventory management systems help businesses assign, manage, and track SKUs efficiently, saving time and mitigating the risk of human error. There are even tools that can automatically generate SKUs for you, such as:

Structuring Your SKU – An Example

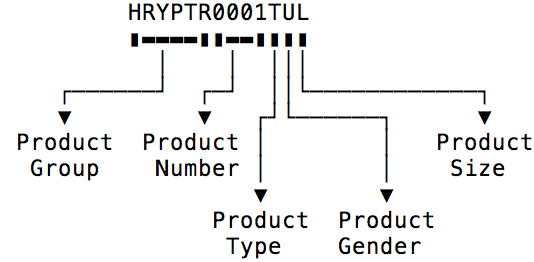

Here is an example SKU of HRYPTR0001TUL to demonstrate the components of a good product SKU:

Each portion of the SKU is broken up into distinct sections. It is worth noting, as a guideline:

- Each SKU section should always be the same number of characters across all SKUs. Meaning, if the Product Group is six characters, it should be six characters for all cases. This allows you to always grab the same number of characters in the same location of the SKU to grab the corresponding section.

- Since each SKU section will always be the same number of characters, you must plan ahead to determine possible future use-cases.

- The sections and lengths used here are just an example. You should choose sections and lengths appropriate to your store.

Using the example SKU above, here is an explanation of each section:

- Product Group: This example has a six-character section for grouping products. In this case, the product is for Harry Potter, so the section is HRYPTR. All Harry Potter item SKUs would start with HRYPTR, which makes it easy to see at a glance.

- Product Number: The product number is a way to allow future products within this group to be created by just incrementing this number. If you only use numbers, this allows for 10 values per character, for a total of 10,000 different Harry Potter products. If you also include A-Z, this allows for 36 values per character, for a total of 1,679,616 products.

- Product Type: If you sell different types of items, you can add a product type section. In this example, there is only one character allocated, which allows for 36 alphanumeric values. The “T” in this case stands for T-shirts. There may also be other characters, such as “D” for DVDs, “H” for hats, etc.

- Product Gender: Another good attribute to add in the SKU might be gender, if you sell gender-specific items. In this case, the “U” stands for unisex. Other valid values may be “M” for Men’s and “W” for Women’s.

- Product Size: The product size attribute in this case refers to “L” for large. Other valid values may be “S” for small, “M” for medium, etc.

Alternatively, if you don't need to see product attributes in the SKU, you may find it easier to just stick with a product group and product number approach.

Common Mistakes to Avoid

In theory, creating SKUs should be pretty simple and repeatable. But there are a few pitfalls to avoid, such as:

Duplicating SKUs

Simply put: make sure each product has a unique SKU. Assigning duplicate stock-keeping unit numbers to multiple products makes it impossible to accurately track inventory levels.

Using Generic SKUs

Generic SKUs are fine for tiny stores. But if you have more than a handful of products (and are planning to expand your range at some point), your SKUs should provide some kind of meaningful information that speaks to the product’s characteristics.

Changing SKUs Frequently

Once you’ve defined a consistent approach for assigning SKUs, only make changes when it’s absolutely necessary. Otherwise, you risk causing confusion and creating inaccuracies in your inventory tracking process.

Not Tracking SKUs

If you fail to track SKUs over time, it becomes much harder to accurately track inventory levels and identify sales trends.

Using Non-Standard SKUs

Unless you’re happy to manually manage inventory levels and tracking, make sure your SKU system is compatible with inventory management systems and barcode scanners.

Managing SKUs

There are plenty of software types to help businesses manage their stock-keeping units, including:

Inventory Management Systems

As the name suggests, inventory management systems help businesses track inventory levels and manage SKUs. These systems are capable of automating common SKU management tasks, like report generation, order management, and inventory tracking.

Examples include:

ERP Software

ERP systems help with various operations management tasks, including inventory management. Many of these tools include built-in SKU management functionality.

Examples include:

Barcode Scanners

Use barcode scanners to scan and track SKUs in real-time, helping you manage inventory levels and generate robust sales data. Most barcode scanners can be integrated with other SKU management-related tools, including inventory management and ERP systems.

Examples include:

Excel Spreadsheets

Rather than investing in sophisticated (and often expensive) ERP or inventory management software, many small businesses choose to track inventory levels via spreadsheet. They’re not particularly scalable, but they’re highly customizable and easy to update as your product range changes.

Cloud-Based Inventory Management Software

Just like inventory management systems, but based in the cloud — allowing users to access them from anywhere using a computer or mobile device.

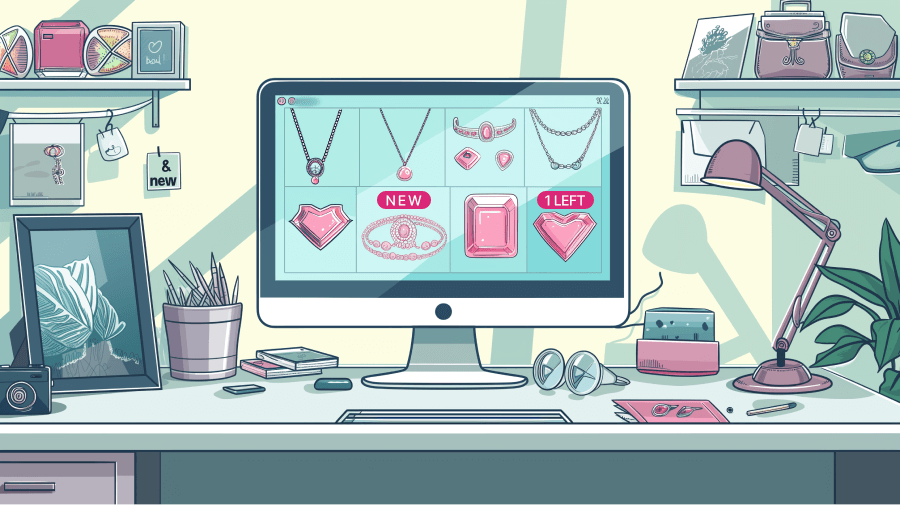

Grow Your Shopify Sales by over 175% with Flair

-

Increase sales using product badges and sales banners

-

Maximize conversions with scarcity, urgency and countdown timers

-

Automate promotions with targeted rules and scheduling

Conclusion

At first glance, stock-keeping units are nothing more than a random alphanumeric code.

But they’re a whole lot more than that.

Once you come up with a meaningful way to assign and track SKUs, they can help you understand sales trends, monitor inventory levels, and follow products from supplier to warehouse to customer.

That means you’re less likely to run out of stock on key product lines or disappoint your customers by failing to fulfill their orders.

Not bad for a few numbers and letters, right?

Other FAQs

Is a Barcode a SKU?

Barcodes are different from SKUs. A barcode is a machine-readable sequence of lines, whereas a SKU is a series of 8 – 12 numbers and/or letters that often denote specific product characteristics, such as manufacturer, product category, size, and color.

How Do I Get a SKU Number For My Product?

SKUs are unique to each retailer, so you need to generate your own. However, there are plenty of tools that can automate the task for you, such as Gorgias, SKUGen, and Zoho Sku Generator.

Does Every Product Have a SKU Number?

Every product should have a SKU number to help retailers differentiate one product from another. However, if a retailer doesn’t take the time to assign a SKU to a product, it won’t have one.

What Is the Difference Between SKU, MPN, GTIN, and ASIN?

SKUs, MPNs, GTINs, and ASINs are all ways to identify a product, but they’re all slightly different:

- SKUs are a retailer’s own unique stock-keeping unit, used for internal inventory management.

- Manufacturer Part Numbers (MPNs) are assigned by the manufacturer, used to identify a specific product from all other products made by the manufacturer in question.

- Global Trade Item Numbers (GTINs) are the series of numbers associated with a barcode and form part of a larger, global data structure for identifying unique products.

- Amazon Standard Identification Numbers (ASINs) are Amazon’s standard identification number, used to identify all products sold on Amazon (other than books, which use another form of identification: ISBN).

Can SKUs Have Letters?

SKUs are alphanumeric codes made up of 8 – 12 numbers and/or letters, such as ABC-101-202.

How Many SKUs Can Shopify Handle?

There is no limit to the number of SKUs you can add to your Shopify store. However, unless you’re a Shopify Plus subscriber, Shopify limits the number of new SKUs you can add per day to 1,000 SKUs once you hit 50,000+ total SKUs.

Are SKUs Necessary for a Shopify Store?

SKUs are totally optional on Shopify. If you’ve only got a small product range (say, no more than a dozen products) and have no plans to expand your portfolio, you can cope perfectly well without them. But if you have tens, hundreds, or thousands of products, you should definitely use SKUs to track inventory levels.

Is the Product’s ID Number the Same As the SKU?

Both SKUs and product IDs are unique codes used to identify specific products. However, they’re not the same thing. One key difference is that retailers can choose and edit SKUs, whereas product IDs are usually assigned automatically and cannot be changed.